Learn More About What Our Machines Are Capable Of

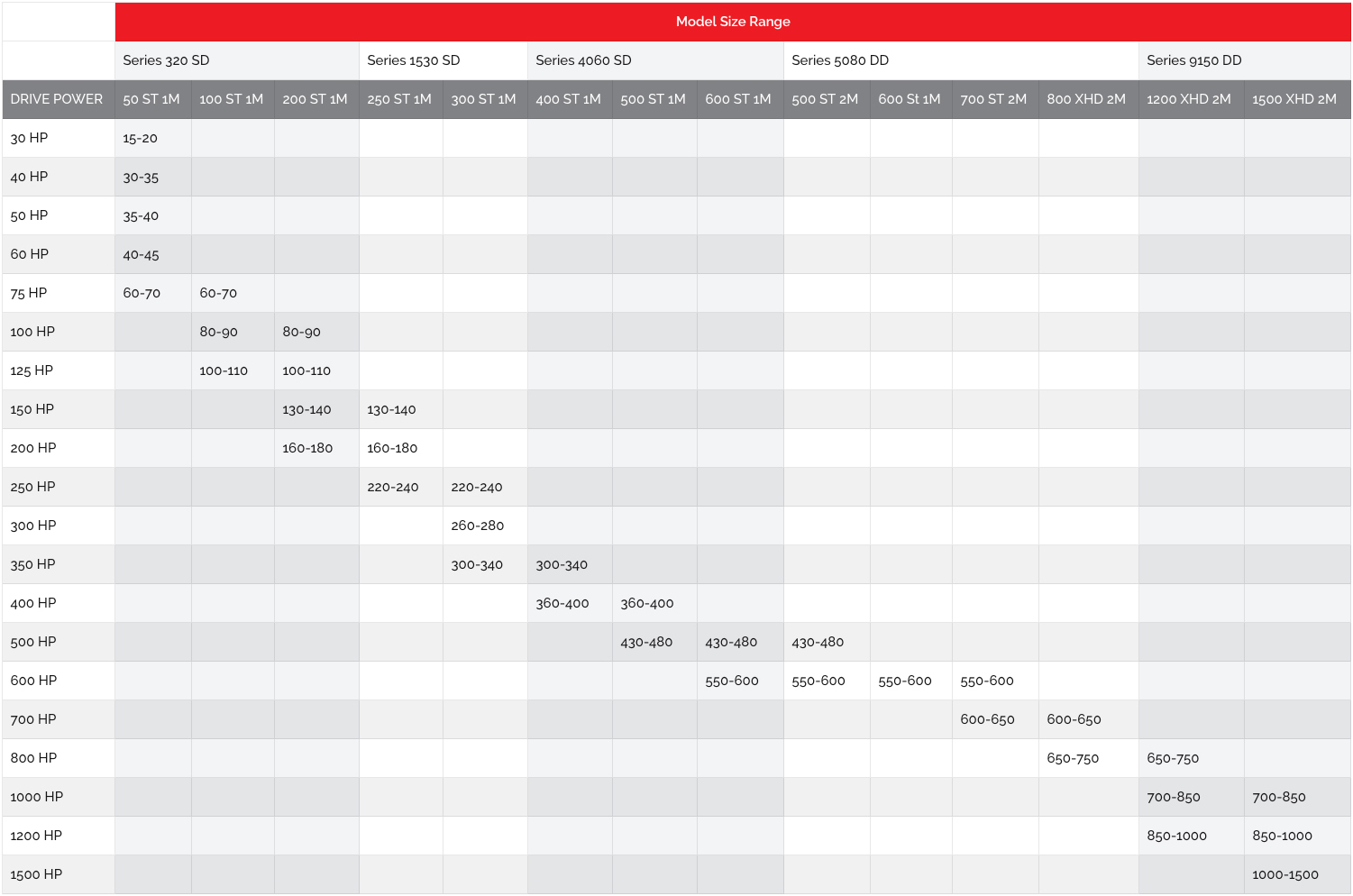

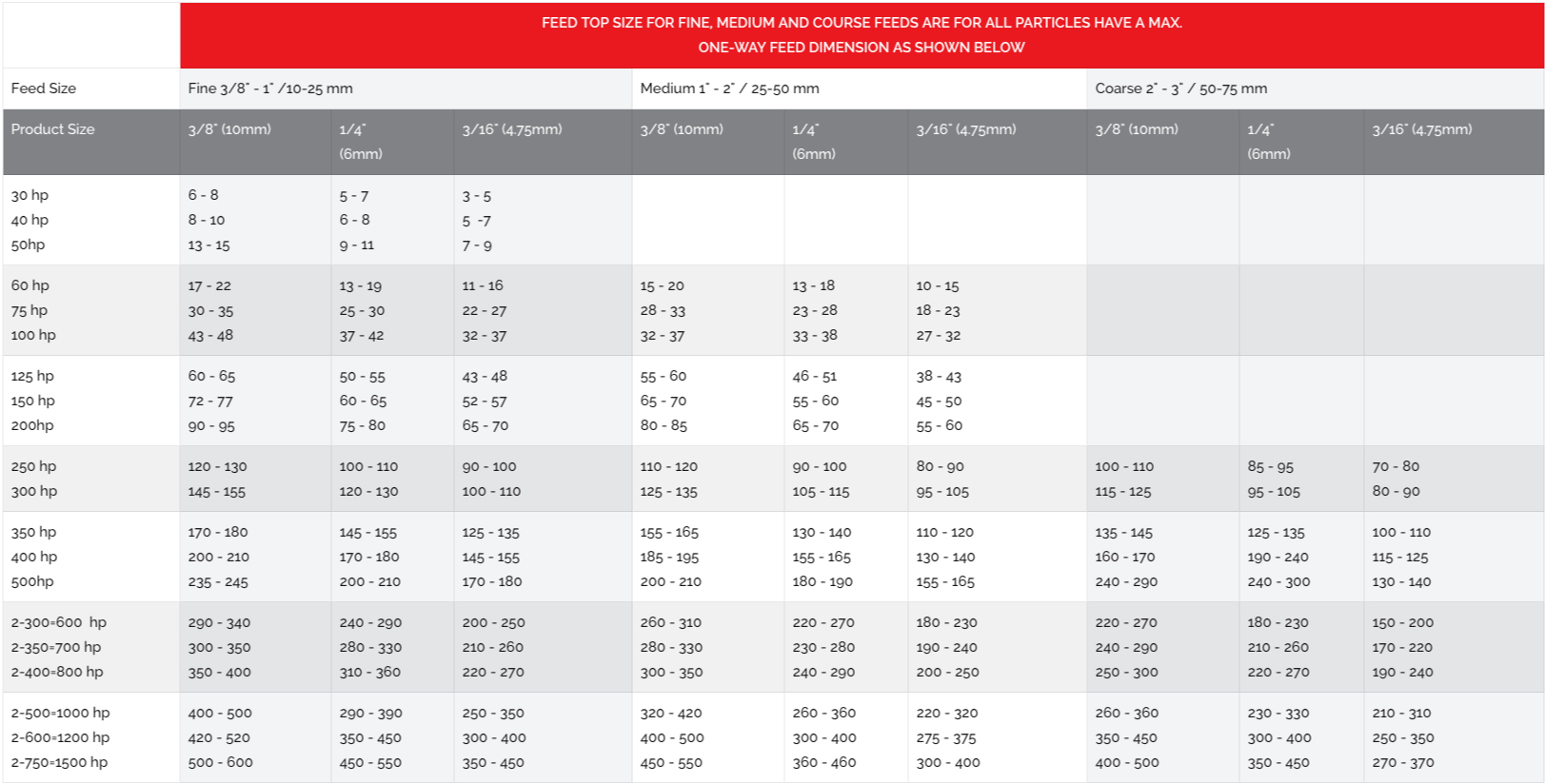

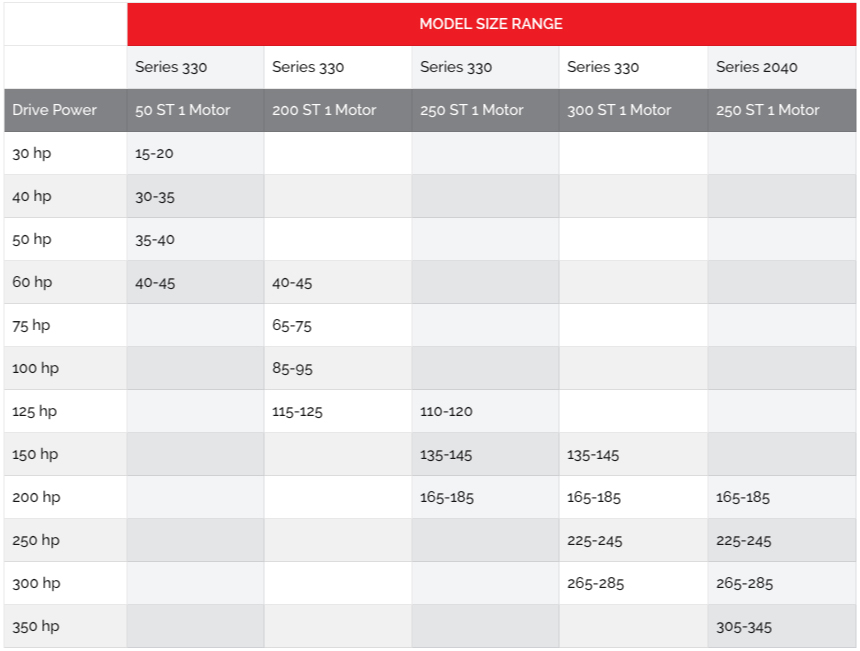

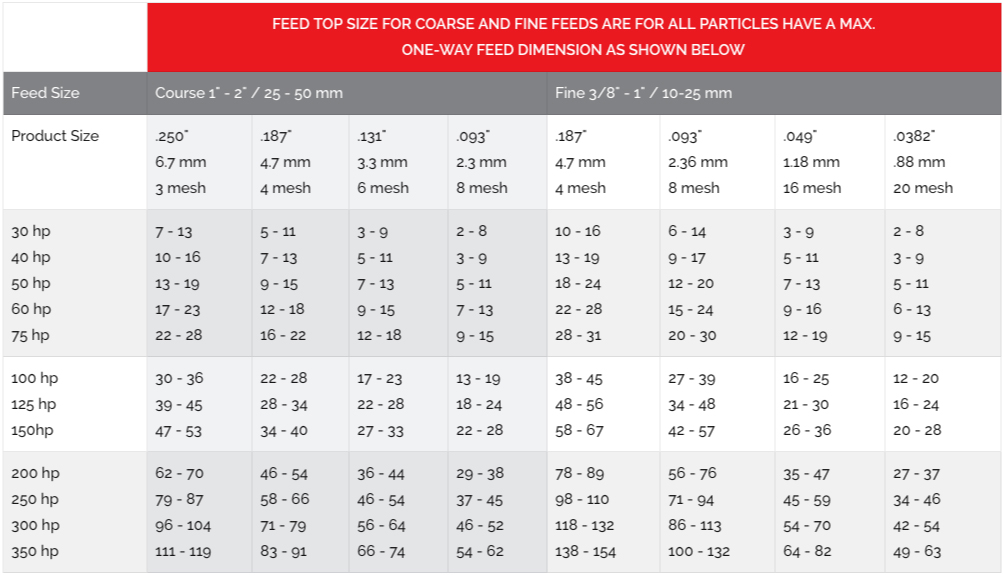

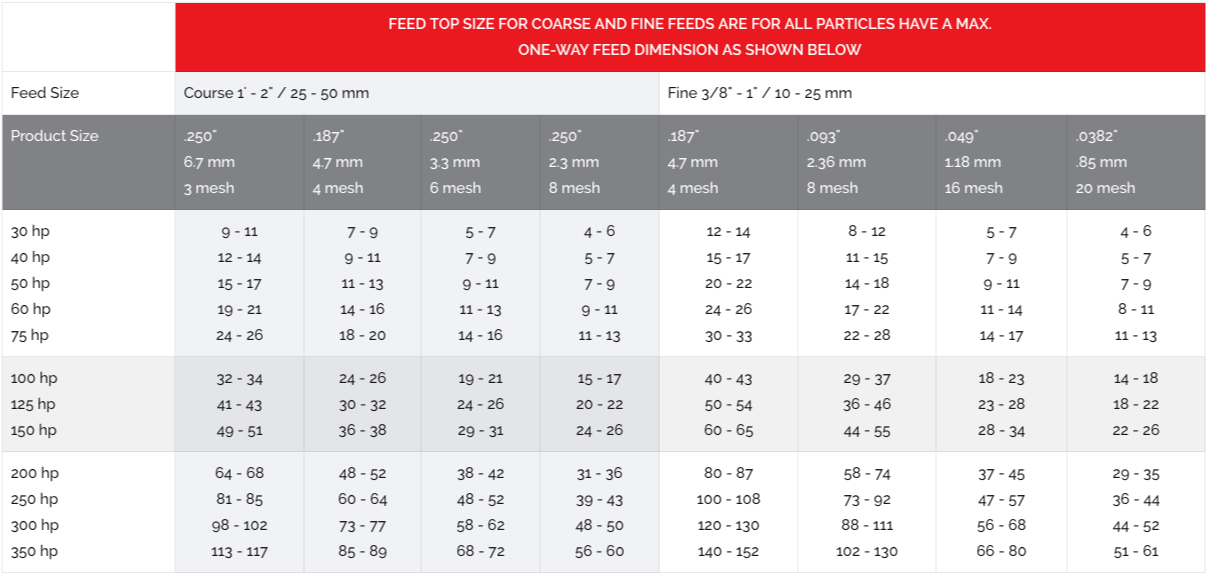

To select the right crusher for your application, please refer to the Basic VSI circuit diagram. REMco impact crushers have two distinct capacities. As you can see from the chart, the sizes are measured at two different points. Understanding this circuit flow is key to the proper crusher model and drive power selection.

For maximum production of the desired product, it is essential to maintain crushing circuit efficiency, which means that the sizing equipment, such as vibrating screens, be accurately selected to handle the maximum production of the VSI crusher. In VSI circuits, the products in demand are usually 3/4" (20 mm) or smaller. The size can present a challenge to the screening device, and REMco recommends that it be conservatively selected.

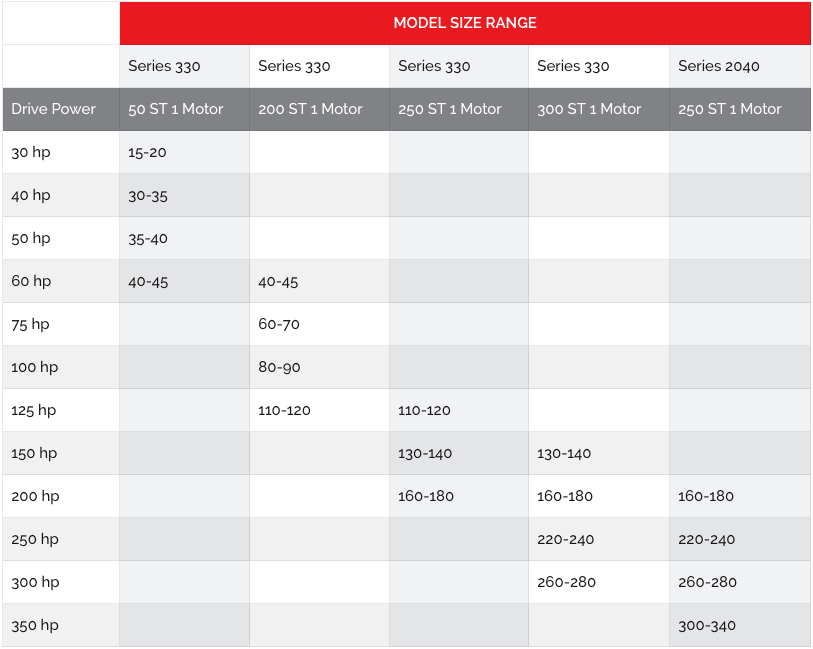

Selecting the drive motor to power a REMco VSI crusher is of utmost importance. Not all electric motors are equal. Some are not suited for VSI service. Experience has shown that electric motors of heavy duty construction will provide longer service and superior crusher performance.

The electric motor power rating in HP or KW needs to be carefully sized to the desired production rate. The REMco capacity charts are based on machine drive powers followed over many years and hundreds of installations. But, some materials may have unique processing or crushing characteristics. In those cases, we suggest that you contact us for additional guidance.

In some instances extremely fine products, generally below 1/16" (2 mm), it may be necessary to use air separation devices instead of a mechanical sizer. These applications require careful study and analysis.